Laser Cut Ramp

Height Adjuster

The 2W loading chute has laser cutouts to adjust the height of the ramp to accommodate for high or low loading trailers.

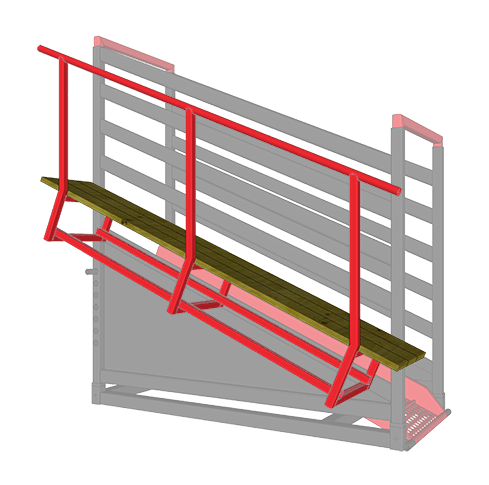

Steel Railing with

Wooden Catwalk

A steel railing is paired with replaceable walk-along floor boards to help handlers move cattle through the chute and to offer increased visibility of the livestock.

Corrugated Steel

Floor for Cleanliness

Laser cut corrugated steel flooring allows for easy clean-up of the chute, and also offers the livestock scaling the chute to have more traction, reducing any sort of potential trips or falls.